OEM solutions - your product is only as good as its components

Here is your new reliable small batch supplier.

Your reliable small series supplier of

OEM components and OEM systems

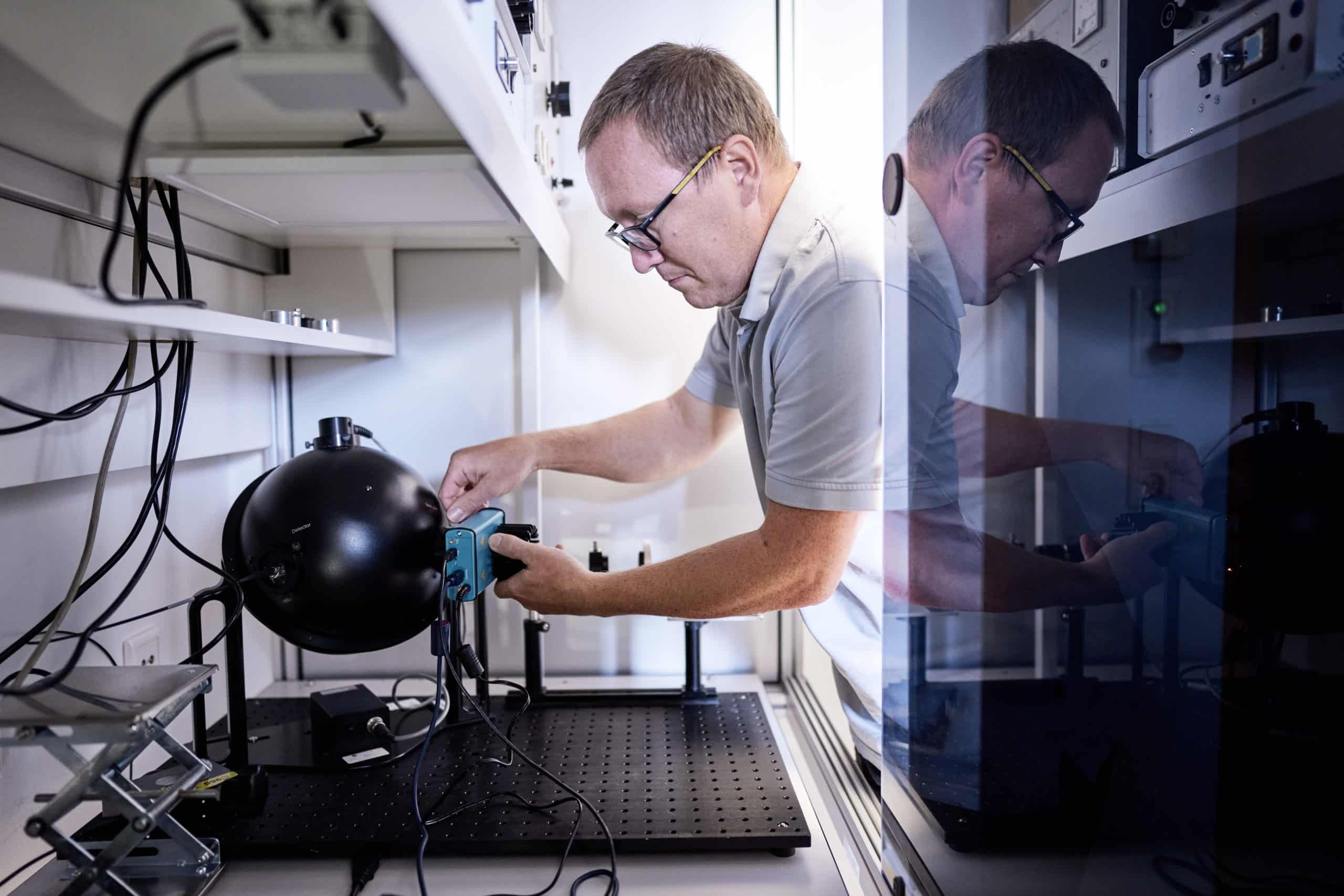

We see ourselves as your agile development partner with lean processes, flat hierarchy and in-house prototype production

How we work

Benefit from the conceptual approach of our development department, which designs complex mechatronic and opto-electronic assemblies and systems according to specific requirements.

We manufacture and test your prototypes directly at our site. This fast, agile way of working has proven itself many times over with our customers.

Once series production readiness has been achieved in an iterative procedure, we are at your side as a reliable supplier for small and medium series. Here, too, we are quick to meet the customer’s needs because we assemble and test directly on site.

We supply the products either in the LEJ design or as you specify, as a private label product.

Our competences

Our engineering team consists of specialists in the fields of electrical engineering, mechatronics, design and programming.

For our OEM projects, all areas come together at the start of the project and work hand in hand to develop the concept for your product or system. In this way, we ensure that the full know-how of all specialist departments is incorporated into your OEM product and that our valued quality is guaranteed.

Electronics & System Concepts

PCB layout

Mechanics- Design

Prototype production

Thermal concepts

System integration & assembly

Complaint rate significantly below 1%

For us, quality means that our products and service deliver what we promised. That is why we attach great importance to our certification according to DIN EN ISO 9001 and NRTL monitoring by TÜV Süd Product Service GmbH.

What is behind the quality of our products?

- We put a lot of care into the development and optimization of existing and new products. One third of our team are therefore developers.

- We work across departments so that products are viewed comprehensively and potential problems can be identified and solved more quickly.

- We listen to our customers and develop individual solutions. Therefore, many of our series products can be flexibly adapted to customer-specific requirements.